A soaking time period of 24 hrs and a cut-off pressure of 276 kPa were considered for all cycles. Over 12 sets of Huff-and-Puff Experiments, utilizing the pure solvent of carbon dioxide, methane, and mixtures of CO2 and propane, were performed at different operating pressures.

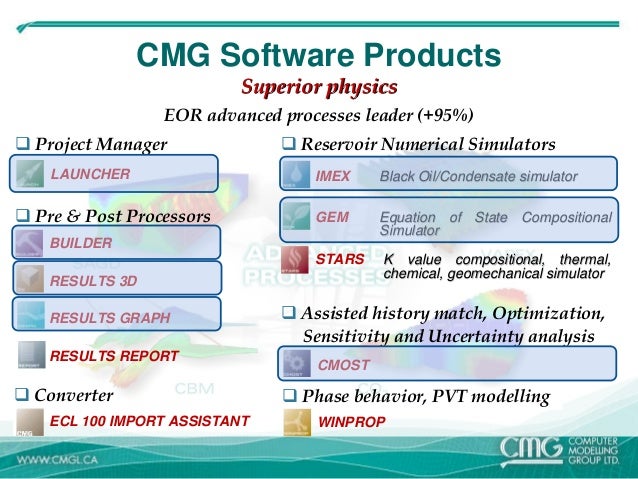

Prior to the tests, a complete phase behavior (PVT) analysis of the oil sample and solvents mixture was conducted using CMG- WinProp(TM) software. Before conducting each Huff-and-Puff Test, the core was saturated with an oil sample representative of Saskatchewan heavy oil reservoirs and exhibited a viscosity of 952 mPa.s, at a temperature of 28☌. The core has a permeability of 1800 md and a porosity of 24% which was mounted in a high pressure, stainless steel core holder. All experiments were conducted in a Berea core with the dimensions of 30.48 cm by 5.07 cm. Thus, both experimental and reservoir simulation approaches were applied and, the impact of the aforementioned parameters on the performance of the process was investigated. This study attempts to validate the feasibility of the Solvent Based Huff-and-Puff Method with respect to enhancing heavy oil recovery and to investigate the effect of fluid, operation, and reservoir parameters on its' performance. Solvent and CO2 Huff-and-Puff are analogies to cyclic steam stimulation however, in this method, steam is replaced with CO2, hydrocarbon solvent or mixture of the two. Over and above solvent based processes, specifically, the cyclic solvent injection well known as "Huff-and-Puff', has demonstrated a significant potential to enhance heavy oil recovery.

0 kommentar(er)

0 kommentar(er)